- Article

Properties of Nanocomposite Ag-Cu Colloids Prepared by Electrical Spark Discharge Method

- Meng-Yun Chung,

- Kuo-Tung Chen and

- Kuo-Hsiung Tseng

- + 2 authors

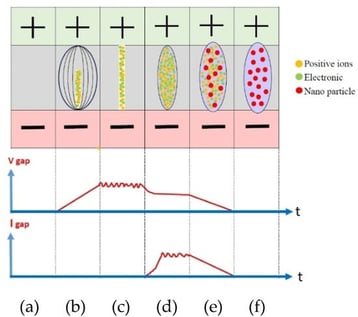

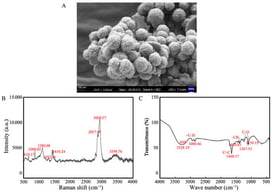

Electrical spark discharge was used to prepare nano Ag–Cu colloids with an electrical discharge machine, deionized water (DW) as the dielectric fluid (DF), and at room temperature and normal pressure. The upper and lower electrodes of the electrical discharge machine were pure Ag and Cu wires or composite metal wires with an Ag–Cu ratio of 92.5:7.5 or 72:28. The optimal Ton–Toff, process time, and current for colloid production were identified as 30–30 µs, 5 min, and approximately 11 A, respectively. The absorbance, characteristic wavelength, particle size distribution, and suspension stability were, respectively, 0.586, 406 nm, 101 nm, and 28.1 mV for the colloids prepared using pure Ag and Cu wires; 0.509, 419 nm, 197.5 nm, and −6.67 mV for the 92.5:7.5 composite wires; and 1.479, 407 nm, 85.27 nm, and14.8 mV for the 72:28 composite wires. The diffraction peaks of the Ag and Cu particles shifted for the composite-produced colloids; this was likely caused by internal structural defects in the composite metal wires. Transmission electron microscopy was used to analyze the nanomaterials. The average Ag and Cu lattice widths, respectively, were 0.234 nm and 0.207 nm for the pure-metal wires, 0.243 nm and 0.210 nm for the 92.5:7.5 composite wires, and 0.243 nm and 0.210 nm for the 72:28 composite wires. X-ray diffraction (XRD) analyses were conducted to determine the crystal orientations of the nano Ag–Cu particles and revealed that nano Ag–Cu colloids prepared using pure Ag and Cu wires had an Ag–Cu particle ratio of approximately 97:3.

7 February 2026